Dump Truck Simulator

The dump truck simulator is an advanced training tool that provides users with a highly realistic experience closely resembling real-world conditions. This system replicates the operation of a dump truck within a cabin modeled after an actual vehicle, combined with specialized software in a controlled virtual environment. Through precise computer-based 3D modeling, the simulator recreates various operational settings, allowing users to enhance their skills in complex and challenging scenarios.

By offering diverse training, skill-development, and hazard-awareness scenarios, as well as simulating traffic incidents based on real cases from domestic mining sites, this simulator effectively prepares users to handle real-world situations. Its advanced interactive capabilities enable users to develop their competencies through practical, hands-on training.

Additionally, the dump truck driving simulator provides accurate feedback along with comprehensive analytical performance reports, enabling precise evaluation and continuous improvement of user skills. This ultimately contributes to increased safety and operational efficiency in industrial environments.

potential customers

Mining companies

Transport fleets

Driving training centers

Construction companies

Necessity for Use by Mining Industry Owners and Product Benefits

Powered by Nasir

Financial benefit and cost reduction

Using simulators significantly reduces training costs by eliminating fuel consumption, minimizing wear and tear on real equipment, and reducing downtime associated with traditional training methods and equipment unavailability. This cost-effective solution ensures long-term savings and maximizes return on investment. Virtual training and simulator-based instruction help reduce or eliminate the following expenses, ultimately preserving capital:

- Vehicle wear and tear

- Fuel costs

- High costs of training with real vehicles

- Equipment downtime

- Significant expenses caused by operator errors, damages, and equipment losses

Powered by Nasir

Increased Productivity and Efficiency

Simulators greatly streamline the training process, enabling operators to practice and master complex maneuvers in a controlled environment. Access to real machinery for hands-on practice is often challenging; therefore, simulators accelerate skill development, reduce training time, and ensure operators are fully prepared, proficient, and capable for real-world operations. As a result, overall productivity increases.

Powered by Nasir

Higher safety level

These are real images from mining sites in Iran. Simulator-based training provides a completely safe, risk-free environment where operators can practice and improve their skills without the danger of accidents or damage to equipment. This emphasis on safety reduces the likelihood of workplace incidents, creates a safer work environment, and enhances compliance with professional safety standards.

- Reduction in fatalities

- Decrease in damage and accident rates

- High-risk nature of real-vehicle training eliminated

- Reduced potential driving hazards and accidental risks

- Enhanced employee safety

Keeping Up with Global Technologies

Integrating modern technologies and advanced simulation systems into training programs provides an immersive and highly realistic experience while raising workplace standards. Simulators can recreate and repeat various scenarios and conditions, offering customized training tailored to the needs of specific mining sites. This technology-driven approach ensures operators are trained according to the latest innovations and best practices in the industry.

Components of the Dump Truck Simulator

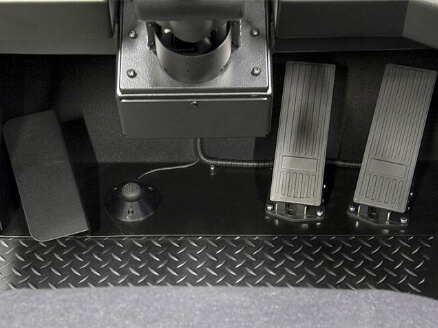

Pedals

Use of pedals that match real and industry-standard vehicle samples for accelerator and brake pedals (hydraulic and electric), providing interactive force feedback to the user.

Seat Motion System

A two-degrees-of-freedom motion platform (pitch and roll) for the operator’s seat, designed to simulate and apply real-time movements caused by road and environmental forces to the cabin and operator, with software integration capability.

Seat Vibration System

Simulation of vibrations generated by the powertrain and transmitted to cabin components and the operator, with adjustable impact intensity and vibration frequency to replicate all operating conditions of different vehicle powertrains.

Vehicle Seat

Use of a real dump truck vehicle seat with adjustable longitudinal position, adjustable backrest angle, and armrests.

Automatic and Manual Gear Selector

Use of an automatic transmission with manual mode capability, covering both manual and automatic vehicle types.

Vehicle Dashboard

Use of a dashboard matching real vehicle samples to enhance immersion and increase operator familiarity with the cabin interior.

Various Settings

Use of all in-cabin control components based on real and industry-standard vehicle designs, with ergonomic and standards-compliant placement of all controls.

Steering System

Use of a vehicle steering system supporting various steering wheels and an adjustable steering return mechanism to provide haptic interaction with the user, including adjustable steering stiffness and response speed.

Display

Display of the simulator’s virtual environment using a video projector or three displays, along with a monitor mounting system offering height and angle adjustment, foldability, longitudinal and lateral movement, and high stability and structural strength.

Service and Support

Our exceptional commitment in providing the most comprehensive and best services and support to our customers is exemplary in this industry. Our customers are our most valuable asset and this is not just a slogan.

12 months product warranty

24 hour support

After sales service

Continuous software updates

Fast maintenance

Portable Dump Truck Simulator with Container Unit

The portable simulator is designed to meet the dynamic needs of the mining industry. It provides a flexible and effective training solution that can be transported directly to the mining site. With this product, you can enhance workforce skills and safety on-site while monitoring operator driving behavior.

Mobility in Mining Sites and Time Savings

In this product, the simulator system is housed inside a container that can be easily transported by truck to any mining site, allowing seamless on-site training without logistical complications. This makes it an ideal solution for mining operations, providing flexibility for operator training across multiple locations. The simulator cabin can be placed near the work zone, reducing time and training-related costs while ensuring all operators, regardless of site location, receive high-quality instruction.

Durability and Cost-Effective Construction

The simulator cabin is built inside a durable 20-foot container, making it easy to relocate without requiring complex infrastructure. This container-based design allows the simulator to operate in various environmental and geographical conditions. The sturdy, lockable structure protects internal equipment from damage. Training costs are reduced by eliminating the need for travel and minimizing downtime associated with off-site training.

Effective and Efficient Training

The simulator cabin provides an isolated environment that minimizes distractions and enhances user focus. A dedicated instructor room is equipped with essential tools for precise driver monitoring and performance evaluation. Advanced control systems, including cameras and monitoring devices, are integrated to improve training quality and ensure accurate oversight.

Customization

This product can be manufactured in various dimensions and cabin configurations based on customer needs and available space. It can also accommodate multiple simulators or additional systems such as excavator simulators, custom-built according to the client’s specific operational requirements.